AHOY, MATEY!

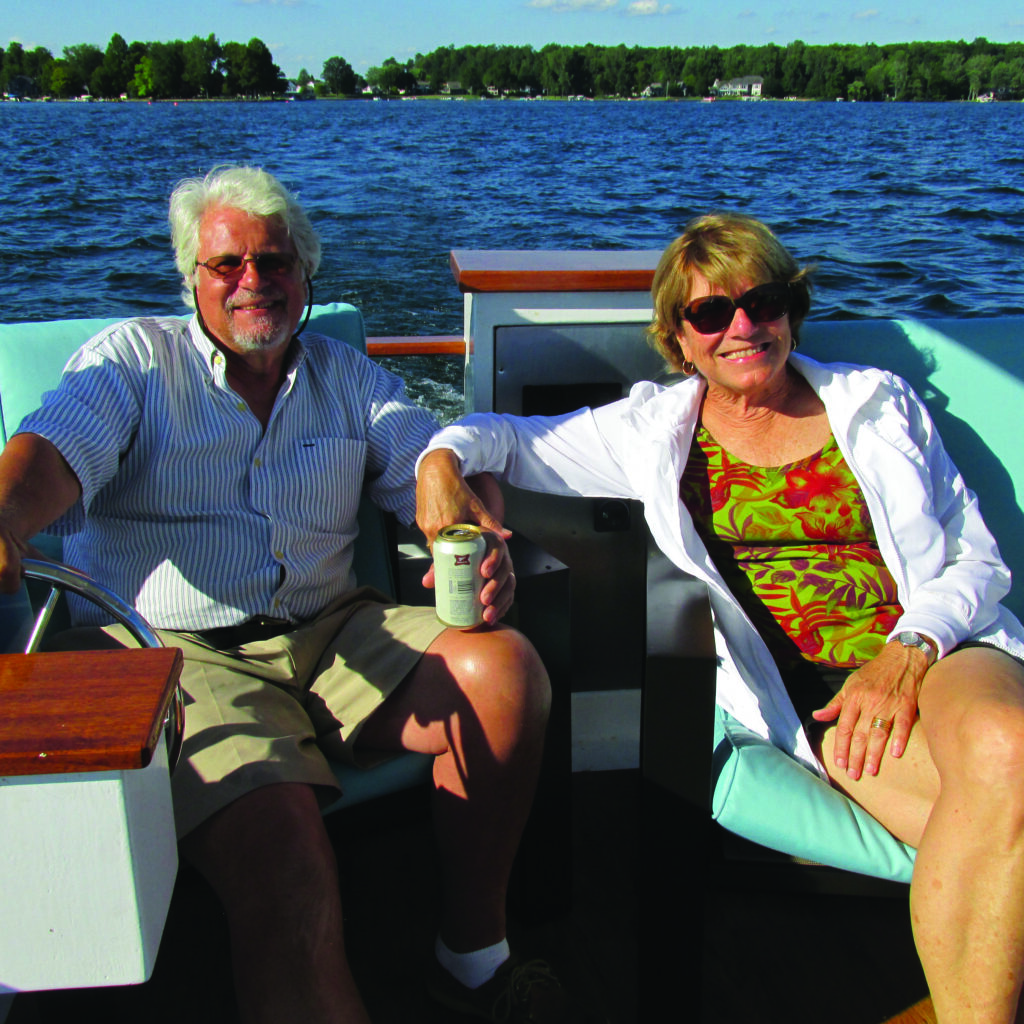

By Bill & Renate Brenneke

You have heard of pontoons and tri-toons. Well, Lake George now has what is called a “newtoon.” Residents Bill and Renate Brenneke designed the new boat as a low-speed alternative to the pontoon type and built it in about a year.

You have heard of pontoons and tri-toons. Well, Lake George now has what is called a “newtoon.” Residents Bill and Renate Brenneke designed the new boat as a low-speed alternative to the pontoon type and built it in about a year.

Bill is a retired architect, after spending 40 years in the business. Renate is a retired educator. Bill’s family has had a cottage on Lake George since 1953.

The “newtoon” idea began when they were considering the purchase of a pontoon boat but the current choices weren’t exactly what they had in mind. Bill wanted something distinctive and pretty on the water. Comfort and convenience were also primary objectives. The boat was to be used for low-speed touring on Lake George. Since they couldn’t find what they wanted, they decided to build it.

Design

Bill started to design the project and then proceeded with construction drawings, hoping to start building in the early fall. With limited experience in boat building, he solicited guidance from Arch Davis, an experienced boat designer and builder in Maine. His help proved invaluable, especially with respect to the hull bottom shape and framing.

Construction and Materials

Hull materials were chosen for strength and rot resistance. Okoume plywood, a rot-resistant plywood that is fabricated with wood similar to mahogany, was the best choice even though it costs four times as much as regular plywood.

All surfaces were covered with a two-coat barrier of epoxy. Surfaces subject to wear were covered with eight-ounce fiberglass cloth set in epoxy. In all, about 10 gallons of epoxy were used.

The deck was designed to be an open deck with no built-in seating and the only fixed element was to be a steering wheel bracket. Seating was to be comfortable, durable and versatile patio furniture. No cover was required because the deck would be self-draining through scuppers. This design meant that trips out on the lake would be just “hop and go.”

Commitment

After final design plans were complete, it was time to take the big dive into actually building the boat. Although skeptics abounded, the decision was made to proceed down the long scary path of building a 23-foot boat. The first step was to purchase nearly $5,000 worth of epoxy and okoume marine plywood.

The second step was finding adequate space to build this new rig. A neighbor offered his garage in which to build the boat over the winter. However, the two-car garage turned out to be a little too small and had inadequate electrical power. So, a small tarp addition was erected and electrical was supplemented with a generator.

With these modifications, the space became ideal. It was close to Bill’s workshop, which was equipped with the necessary tools and equipment, allowing many components to be prefabricated.

The exposed surfaces were either varnished mahogany (trim) or painted with marine-pigmented polyurethane. Since no lift was to be used, the hull bottom was painted with a hull paint designed to resist marine growth.

After construction was complete, they were ready to add power. To provide propulsion, they decided on a 20hp Elco electric motor running on 48 volts, which is provided by four 12-volt lead-acid batteries.

As with most wooden boats, this one was built upside down until the bottom was complete and ready for the water. In order to finish the boat, it had to be pulled out of the garage, turned over and then returned to the garage. This was no small feat since the boat weighed 1,200 pounds at that point.

To accomplish this, Bill solicited the help of his friend Skip Davenport, of Davenport Excavation, who brought his largest backhoe. With many onlookers “supervising,” there were tense moments when the boat first dangled in the air and then was set down on edge and finally pulled over onto a skid assembly.

During this ordeal there were other tense (and sometimes funny) moments too. Patience was a virtue as they mixed up 10 gallons of epoxy in five-ounce batches. Bill had the only real injury after making a concrete face plant while getting off the rig at one point.

The most memorable mishap was when Bill got a belt sander hopelessly caught in his pant leg. Unable to free the sander, he enlisted the help of a neighbor who was passing by with a sharp knife. Mistakes were made along the way, but overall things went pretty smoothly with lots of laughs and a few adult beverages to keep things moving right along.

The Naming

Many sources offered ideas for a name but, in the end, she was christened Maiden Kope Kon, a fitting name since the owners live on Kope Kon Pt.

The Launch

By July, the boat was ready to launch. After being loaded onto a trailer it made its way to the Lake George launch site, where friends were waiting to watch its maiden voyage. As it was unloaded into the water, folks held their breath and wondered, “Would it float and would it work?”

Indeed, it did float and it did work, making a victory lap around Lake George. A new tradition was also born after the first voyage. To celebrate success, they had a “burning of the pants party” to dispose of pants made stiff after months of being worn to apply coats of epoxy, paint and sawdust.

The first “newtoon” has become a familiar sight on summer evenings as it quietly makes its way around Lake George. When Bill and Renate aren’t on the water with their new “baby,” he spends his free time designing and building unique projects that he had no time for previously and she is either quilting or volunteering in the community.

Share this article

Popular articles

Subscribe to our mailing list

Get the latest Lake Access news and articles delivered straight to your inbox.